Graph_Convolutional_Neural_Network_for_Intelligent_Fault_Diagnosis_of_Machines_via_Knowledge_Graph.pdf

免费下载

7862 IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS, VOL. 20, NO. 5, MAY 2024

Graph Convolutional Neural Network for

Intelligent Fault Diagnosis of Machines

via Knowledge Graph

Zehui Mao , Senior Member, IEEE, Huan Wang , Bin Jiang , Fellow, IEEE, Juan Xu , Member, IEEE,

and Huifeng Guo

Abstract—Considering the challenge of deep mining of

root causes in machine failures, a knowledge aggrega-

tion fault diagnosis (KAFD) model is proposed, in which

the graph convolutional network (GCN) GraphSAGE is im-

proved and introduced into the knowledge graph (KG)-

based fault diagnosis. Historical maintenance data of ma-

chines is used to construct a fault phenomenon-FBG,

which is then combined with the fault diagnosis knowledge

graph (FDKG) to form a collaborative FDKG. A single-layer

knowledge aggregation network (KAN) that incorporates

sensitivity factors and configures different types of GCN

aggregators is constructed in the proposed KAFD. Based

on deep neighbor aggregation operations on collaborative

FDKG, KAFD obtained by stacking multiple KANs, can cap-

ture the higher order structural information and semantic

information, which results in the multihop reasoning, im-

provement of the rationality and diversity of fault cause

tracing. The KAFD is experimentally validated through two

fault diagnosis datasets, which are constructed by the

maintenance data of an industrial enterprise, and the re-

sults demonstrate the excellent performance.

Index Terms—Fault diagnosis, graph neural networks,

industrial machines, knowledge graph (KG).

I. INTRODUCTION

I

NDUSTRIAL machines have been becoming more complex

and expensive with the high performance, as the advanced

intelligent devices and monitoring technologies are introduced

Manuscript received 23 October 2023; revised 10 December 2023;

accepted 6 February 2024. Date of publication 29 February 2024; date

of current version 6 May 2024. This work was supported in part by the

National Key Research and Development Program of China under Grant

2021YFB3301300 and in part by ZTE Industry-University-Institute Co-

operation Funds. Paper no. TII-23-3628. (Corresponding author: Juan

Xu.)

Zehui Mao, Huan Wang, and Bin Jiang are with the College of

Automation Engineering, Nanjing University of Aeronautics and As-

tronautics, Nanjing 210016, China (e-mail: zehuimao@nuaa.edu.cn;

wanghuan233@nuaa.edu.cn; binjiang@nuaa.edu.cn).

Juan Xu is with the College of Computer Science and Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016,

China (e-mail: juanxu@nuaa.edu.cn).

Huifeng Guo is with the State Key Laboratory of Mobile Network and

Mobile Multimedia Technology, Shenzhen 518000, China, and also with

the ZTE Corporation, Shenzhen 518000, China (e-mail: guo.huifeng2

@zte.com.cn).

Color versions of one or more figures in this article are available at

https://doi.org/10.1109/TII.2024.3367010.

Digital Object Identifier 10.1109/TII.2024.3367010

into them. However, this leads to an increasing requirement on

reliability and safety of industrial machines subjected to faults

and failures [1]. Fault diagnosis that detects the occurrence of a

fault as early as possible and identifies the location and type of

the fault as accurately as possible, is a key mean to ensure the

safety of industrial machines [2], [3].

With the development of technology, the fault diagnosis

methods are receiving more and more attention, including the

model-based methods [4], [5], data driven-based methods [6],

[7], [8], [9], and knowledge-based methods [10]. As a significant

amount of maintenance records can be accumulated during the

long-term maintenance and repair processes of industrial ma-

chines, which contain the valuable knowledge and information

related to machine fault diagnosis.

Knowledge-based fault diagnosis methods commonly include

expert systems, fault tree analysis, and knowledge graphs (KGs).

By automating the acquisition, organization, and analysis of

various machine information, including maintenance history and

expert experience, KG-based fault diagnosis methods can iden-

tify fault root causes and provide solutions. Existing research

mainly utilizes KG reasoning techniques [11], [12], [13], which

can make inferences about potential causes or solutions based

on entities and relations. During the machine operating, the

new data and information reflecting new faults often emerge

often generates. Incorporating new data and information into

existing KGs and reasoning requires offline updates, difficult to

be updated and improved dynamically.

Recommendation systems, by continuously collecting feed-

back from maintenance personnel during the maintenance pro-

cess, can achieve dynamic updates and continuously improve

the accuracy of fault cause recommendations, addressing the

issue of dynamic updates in KG-based fault diagnosis. Fusing

the KGs and recommendation algorithms can address the issue

of dynamic updates in KG-based fault diagnosis, which can be

primarily achieved through the propagation-based methods [14],

[15]. Propagation-based methods can expand the depth of infor-

mation reception by following the deep aggregation, thereby

fully utilizing the information in the KG to better predict fault

causes and locate potential fault causes. Deep aggregation is

the core of graph convolutional neural networks (GCN) [16],in

which GraphSAGE [17] is a representative model. But GCNs

like GraphSAGE is not feasible for weighted graphs, as they

can only perform equally weighted aggregations of neighboring

1551-3203 © 2024 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See https://www.ieee.org/publications/rights/index.html for more information.

Authorized licensed use limited to: ZTE CORPORATION. Downloaded on November 26,2024 at 06:05:55 UTC from IEEE Xplore. Restrictions apply.

MAO et al.: GRAPH CONVOLUTIONAL NEURAL NETWORK FOR INTELLIGENT FAULT DIAGNOSIS OF MACHINES VIA KNOWLEDGE GRAPH 7863

nodes. In addition, GraphSAGE imposes limitations on the

number of sampled neighbors, leading to the loss of important

local information for some nodes and making it unsuitable

for representation learning tasks in KGs and requiring further

improvements.

This article aims to address the challenges of difficult fault

knowledge mining and low real-time performance by combining

KGs with recommendation systems. To tackle these challenges,

a novel knowledge aggregation fault diagnosis (KAFD) model

is proposed. The main contributions of this article are as follows.

1) As KGs and recommendation algorithms are combined

and introduced into the industrial machine fault diagnosis,

a new knowledge aggregation network (KAN) is de-

signed, which incorporates sensitivity factor to make the

GCN suitable for the structure of fault diagnosis knowl-

edge graph (FDKG). This design allows for weighted

operations on different nodes of the FDKG, considering

the importance of different neighboring entities.

2) The deep aggregation idea is applied, and the KAFD

model is constructed. By stacking KAN, KAFD expands

the depth of information reception, facilitating multihop

reasoning in the KG and further exploration of potential

fault causes.

The rest of this article are organized as follows. Section II

describes the fault diagnosis problem based on KGs. Section III

introduces the structure of the KAFD model. Section IV presents

and analyzes the performance of the KAFD model. Finally,

Section V concludes this article.

II. P

ROBLEM FORMULATION

This section analyzes the task of KG-based fault diagnosis

for industrial machines, and provides a formulation to describe

the fault diagnosis problem achieved by recommending the fault

root cause from the fault phenomenon.

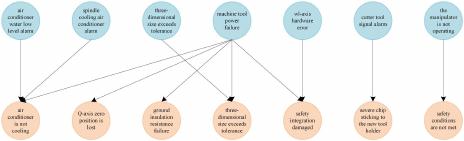

A. Fault Phenomenon-Fault Root Cause Bipartite Graph

(FBG)

For fault diagnosis, recommendation system determines the

root cause of the fault from the fault phenomenon. In the

recommendation system, associations between fault phenom-

ena and causes are represented as an FBG defined as U =

{y

fs

|f ∈F,s∈S}, where F is the set of fault phenomena,

S is the set of fault root causes, and y

fs

correlation between

fault root causes and fault phenomena as

y

fs

=

1,fand s have connection in history

0, otherwise.

. (1)

Due to the sparsity problem of the practical fault data from

the industrial machines, numerous node in the generated fault

bipartite graph only have a few correlative connections, as shown

in Fig. 1, where blue circles are the fault phenomenon and red

circle are the fault root causes. The sparse correlative connec-

tions cause some information missed in the recommendation

system, and the associations between fault phenomena and fault

root causes cannot be accurately expressed, which effect the

Fig. 1. Example of an FBG sparsity problem.

accuracy of fault diagnosis. However, the FDKG, established us-

ing the triples obtained by the knowledge extraction technology,

contains the substantial knowledge about faults. An extra KG can

help supplement the information and improve the representation

of the associations in FBG [18].

B. Fault Diagnosis Knowledge Graph

The method of taking FDKGs as auxiliary information of the

recommendation system contributes to enrich the representation

of fault phenomena and root causes, relieves the sparsity problem

of fault data, and enhances the accuracy and interpretability of

the model.

Similar to the generic KG, FDKG consists of a large number of

triples (h, r, t) as the basic units, denoted as G = {(h, r, t)|h, t ∈

E,r ∈R}, where E is the set of all entities, and R represents

the set of all relations. In the KG, facts are expressed as triples

(head entity, relation, tail entity), which are interconnected to

express real-world knowledge and facilitate computer under-

standing. In the FDKG, facts are expressed as triples (head

entity, relation, tail entity), which interconnect each other to

express knowledge for computer understanding. In this study, the

FDKG is constructed by unstructured data of industrial machines

accumulated during the production process.

C. Collaborative Knowledge Graph (CKG)

As the FDKG and the FBG are established using the different

and independent information of fault data, a CKG which can

associates these two graphs into a unified relational network to

unify the two parts of information, is necessary. The associations

between the fault phenomenon and the fault root cause are

expressed in the form of triples (phenomenon, connect, cause)

in the CKG, where y

fs

= 1 denotes as an additional relation

connect between f and s. Define the alignment set as A, which

denotes that the root cause s of the fault in the FBG can be

aligned to the entity e in the FDKG. Based on the alignment

set A, the FBG and the FDKG are combined into a unified

CKG G

= {(h, r, t)|h, t ∈E

,r ∈R

}, where E

= E∪Fand

R

= R∪{connect}.

D. High-Order Relation

In a unified CKG, high-order relations between fault phe-

nomena and root causes could be established by bridging two

entities that not directly connected. Define the L-order connec-

tion between nodes as a high-order relation path e

0

r

1

−→ e

1

r

2

−→

···

r

L

−→ e

L

, where r

l

∈E

, r

l

∈R

, l ∈ L. More correlation

information between entities could be obtained. As illustrated

Authorized licensed use limited to: ZTE CORPORATION. Downloaded on November 26,2024 at 06:05:55 UTC from IEEE Xplore. Restrictions apply.

of 9

免费下载

【版权声明】本文为墨天轮用户原创内容,转载时必须标注文档的来源(墨天轮),文档链接,文档作者等基本信息,否则作者和墨天轮有权追究责任。如果您发现墨天轮中有涉嫌抄袭或者侵权的内容,欢迎发送邮件至:contact@modb.pro进行举报,并提供相关证据,一经查实,墨天轮将立刻删除相关内容。

下载排行榜

文档被以下合辑收录

评论