Autonomous Vehicle Testing and Validation Platform Integrated Simulation System with Hardware in the Loop.pdf

50墨值下载

Autonomous Vehicle Testing and Validation Platform:

Integrated Simulation System with Hardware in the Loop*

Yu Chen

1

, Shitao Chen

2

, Tangyike Zhang

3

, Songyi Zhang

4

and Nanning Zheng

5

, Fellow, IEEE

Abstract— With the development of autonomous driving,

offline testing remains an important process allowing low-cost

and efficient validation of vehicle performance and vehicle

control algorithms in multiple virtual scenarios. This paper

aims to propose a novel simulation platform with hardware

in the loop (HiL). This platform comprises of four layers: the

vehicle simulation layer, the virtual sensors layer, the virtual

environment layer and the Electronic Control Unit (ECU)

layer for hardware control. Our platform has attained multiple

capabilities: (1) it enables the construction and simulation of

kinematic car models, various sensors and virtual testing fields;

(2) it performs a closed-loop evaluation of scene perception,

path planning, decision-making and vehicle control algorithms,

whilst also having multi-agent interaction system; (3) it further

enables rapid migrations of control and decision-making algo-

rithms from the virtual environment to real self-driving cars.

In order to verify the effectiveness of our simulation platform,

several experiments have been performed with self-defined car

models in virtual scenarios of a public road and an open parking

lot and the results are substantial.

I. INTRODUCTION

Online and offline tests are two major approaches used

in order to verify and optimize the perception and control

algorithms of self-driving cars. Motivated by the necessity

for new applicable technologies in autonomous driving,

offline testing is transforming into a mandatory step for pre-

assessment of top-level control algorithms, before the real

interface application used towards a fully matured level of

autonomous driving [1], [2], [3]. Usually on-site inspection

of physical vehicle behavior is an expensive and time-

consuming attempt that only authorizes a limited number

of scenarios to be tested. By contrast, a simulation test of

vehicle control using mounted sensors and comprehensive

environments provides a reasonable and cost-effective op-

tion. Besides, previous research and experiments on various

intelligent algorithms involved in autonomous driving, in

order to achieve optimal validation results and objective

performance analysis, require an efficient test and validation

platform. Therefore, an efficient simulation platform with

an organized architecture has been proposed, of which the

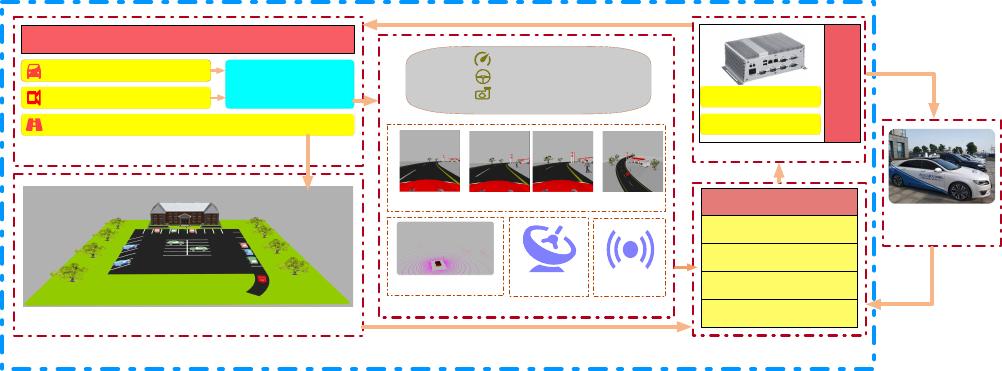

detailed workflow is shown in Fig. 1. This proposed platform

*This research was partially supported by the National Natural Science

Foundation of China (No. 61773312, 61790563), the Programme of Intro-

ducing Talents of Discipline to University (No. B13043).

Yu Chen

1

, Shitao Chen

2

, Tangyike Zhang

3

, Songyi Zhang

4

are with Institute of Artificial Intelligence and Robotics

in Xi’an Jiaotong University, Xi’an, Shannxi, P.R.China

e-mail:{alan19960212, chenshitao, ericzhang,

zhangsongyi}@stu.xjtu.edu.cn

Nanning Zheng

5

is the director of Institute of Artificial Intelligence

and Robotics, Xi’an Jiaotong University, Xi’an, Shannxi, P.R.China

Correspondence: nnzheng@mail.xjtu.edu.cn

contains a software simulation interface and a hardware ECU

interface which have been combined to form a closed test

and validation loop with high efficiency. For one thing, the

software simulation interface mainly consists of 3 layers:

(1) the kinematic vehicle designing layer for vehicle motion

control, (2) the multiple sensors’ simulation layer to percept

environments and assemble data for autonomous vehicles,

(3)the virtual testing environment layer to simulate real

scenarios and also extreme testing situations. Furthermore,

the hardware ECU interface contains an essential electronic

control unit layer for the overall hardware control.

The software simulation interface comprises a variety of

softwares which can simulate any of the required objects to

be evaluated on a virtual test bed. The software simulation in-

terface of the proposed platform is centered around the Robot

Operating System (ROS) and its embedded software Gazebo

[4], [5]. ROS is a robotic software platform that provides sim-

ilar operating system functions for heterogeneous computer

clusters. It offers customary operating system services such

as hardware abstraction, underlying device control, common

feature implementation, inter-process messaging and packet

management. A node is the core component of ROS graph

architecture. It’s usually a short piece of code scripted in

programming language Python or C ++ to perform a rela-

tively simple task or process. Multiple nodes communicate

messages to each other and can be independently started or

terminated. Therefore, nodes at different points of a process

can accept, publish, and aggregate various categories of

information for sensing, controlling, status monitoring or any

other specific purpose. Further to this, Gazebo is a ROS built-

in 3D simulation software that helps to accurately construct

and evaluate the kinematics of robots in complex indoor

and outdoor environments. It offers high-fidelity physical

simulations, a large set of sensors, and numerous procedural

and user-facing interfaces.

Further to the software simulation interface, a hardware

ECU interface [6] based on HiL simulation system has been

developed. Common offline tests merely tend to evaluate

independent algorithm modules or functions, making it prob-

lematic to easily establish the link between the real car

and the virtual environment easily. However, in this paper

the HiL system is one kind of semi-simulation system with

actual controllers but virtual objects and environments [7],

[8], [9]. Real sensors and loads are replaced by virtual

ones to simulate the real-time physical relationship between

actuators and sensors on a simulated car model [10]. This

subsequently allows the ECU to operate in an electrical

environment that is considerably close to that in a real

2018 IEEE Intelligent Vehicles Symposium (IV)

Changshu, Suzhou, China, June 26-30, 2018

978-1-5386-4451-5/18/$31.00 ©2018 IEEE 949

Real Sensor

Data

Simulated Mtiple Sensors

Vehicle Ki Model

Constructed Simulation Scenario

Embedded Actuator

Control Plugins

Simulation Software Stack

Ultrasound

LiDAR Point Cloud

Localization

Camera Images

Sensor Signals

Speed

Steering

Fuel Percentage

Simulated Scenario

Self-driving

Platform

Core Algorithms

Sensor Fusion

Driving Policy

Perception

Path Planning

ECU

Control Algorithms

Rule Compliance

Vehicle Hardware

CAN

Message

Hardware-in-the-loop Simulation

Fig. 1. Workflow of our HiL-based autonomous vehicle simulation platform. The simulation interface exports sensor signals and vehicle states to a

hardware control unit. Sensor data comes from virtual sensors like LiDAR (Light Detection and Ranging), camera, millimeter radar and all other sensor

devices. Vehicle states include throttle, brake, steering and fuel percentage reports for top-level control of ECU. The ECU then processes the transformed

data with core algorithms and sends corresponding actuator commands to a lower simulation interface after making real-time decisions.

vehicle and performs a series of tests to verify whether

its performance meets our design requirements. In terms of

safety, feasibility and reasonable cost, the HiL simulation

test has become an integral aspect of autonomous driving

development flow, reducing the number of real road tests,

shortening the development time, minimizing the cost and

improving the quality of ECU development.

In this paper, the ECU being tested is connected to the

simulation interface for all-round and systematic tests while

realizing a closed-loop simulation system. The simulation

interface exports sensor signals and vehicle states in real-

time to the ECU via CAN (Controller Area Network) bus

devices for data transmission. Then the ECU monitors and

receives all of the data for further management with core

algorithms. Finally, actuator commands for the vehicle are

directed towards the simulation interface for further vehicle

motion control tests. This system can not only evaluate

the environment perception module of a self-driving car,

but can also carry out further evaluations of path plan-

ning, decision-making and vehicle control algorithms of

autonomous vehicles [11]. Thenceforth, once the algorithms

have succeeded the feasibility and robustness assessments in

a virtual environment, they can be swiftly migrated to a real

autonomous platform for minimum error reporting in actual

testing conditions. The workflow of autonomous vehicle

development guaranties the quality and robustness of our

working platform whilst also avoiding massive unnecessary

systematic problems, and furthermore, offering a functional

development platform in a closed loop. This paper aims

to start with some related research works, following by an

introduction to our general platform. Then we’ll proceed

to the realization of detailed layers. Following this, we’ll

verify the effectiveness of our platform with experiments

of planning and decision-making algorithms. Lastly, we’ll

summarize and look ahead to our future work.

II. RELATED WORK

The offline simulation approach is now widely recognized

and applied to automotive systems thanks to its high effi-

ciency and low cost. Multiple modules utilize this approach

in order to develop and evaluate autonomous softwares with-

out the need for an actual car [12], [13], [14]. Meanwhile,

plenty of work has been conducted around HiL systems in

order to optimize offline test results and improve the control

ability, as is indicated in [6]. [15] evaluated their car’s engine

control with simulated combustion engine in a closed loop.

In [16], Oh et al. concluded that the HiL system is efficient

for vehicle dynamic component testing. However, achieving

flexible simulation interface requires various powerful offline

test softwares. Technically, these softwares can be divided

into two varieties: one aims to test the performance of an

autonomous vehicle’s different parts with real data playback.

The other one is mainly used for initial development of

control and planning algorithms. It is based on synthetic data

simulation of vehicle model, sensors and the environment.

For this paper we have chosen Gazebo for its precise kine-

matic modelling and advanced 3D rendering. Similar open-

source softwares like Euro Truck Simulator 2 and The Open

Racing Car Simulator (TORCS) [17] are frequently used

for training and strengthening control algorithms. Udacity

also opened its autonomous vehicle simulator to the public

recently. Those interested can use this simulator to learn how

to drive a car with deep learning. Apart from applications

on research work, there are also simulation softwares for

commercial purposes of automotive industry, like CarSim

for vehicle dynamics [18], PanoSim for complex vehicle

models and traffic scenarios, PreScan for Advanced Driver

Assistance Systems (ADAS) [19] development as well as

vehicle-to-vehicle (V2V) [20] and vehicle-to-infrastructure

(V2I) [21] applications. From training to testing, all these

simulation platforms are making the idea of autopilot more

950

of 8

50墨值下载

【版权声明】本文为墨天轮用户原创内容,转载时必须标注文档的来源(墨天轮),文档链接,文档作者等基本信息,否则作者和墨天轮有权追究责任。如果您发现墨天轮中有涉嫌抄袭或者侵权的内容,欢迎发送邮件至:contact@modb.pro进行举报,并提供相关证据,一经查实,墨天轮将立刻删除相关内容。

下载排行榜

评论