西门子SIEMENS_基于Fibersim的发动机风扇叶片设计.pdf

50墨值下载

- 1 -

基于FiberSim的发动机风扇叶片设计

洪清泉,孟祥龙,钱攀

上海波客实业有限公司,上海,201203

摘要:众所周知,碳纤维复合材料相较于其他金属材料,具有高比强度、高比刚度、重量轻、能够实现结构功能一体化等明显优势,已经

被用于民品、汽车、轨道交通、航空航天等各种不同领域。西门子公司的FiberSim软件在复合材料设计及工艺领域内具有极其重要的地位,对

于一些造型简单零部件可采用Pro基础模块进行铺层设计,对于高铁、航空行业复杂零部件可采用Elite高级模块进行分区铺层设计。本文通

过阐述FiberSim软件的Volume

Fill体积填充自动生成铺层的功能,对航空发动机风扇叶片进行设计,探索出一套适用于变曲面不等厚零件的铺层设计流程,并能够应用于

不同行业领域中结构形式类似的相关零部件。

关键词:碳纤维 复合材料 铺层设计 体积填充

Design of Engine Fan Blade Based on FiberSim

Qingquan Hong, Xianglong Meng, Pan Qian

Shanghai Aerobook Industrial Co. Ltd, Shanghai, 201203

Abstract: It is well known that carbon fiber composite materials have obvious advantages

such as high specific strength, high specific stiffness, light weight, and integration of

structural functions compared with other metal materials. They have been used in civilian

products, automobiles, rail transportation, aerospace, and other different areas. Siemens

FiberSim software has an extremely important position in the field of composite material

design and processing, Pro modules can be used for layer design for some simple parts, Elite

modules can be used for partition layer design for some parts, such as in high-speed rail and

aerospace industries. This article describes the design method of the fan blades of aero-engine

based on the function of automatically generated layer using Volume Fill of FiberSim

software, to find out a set of design process for unequal thickness parts of curved surface, this

process can also be applied to other related structural parts with similar structure in different

industries.

Key words: CFRP; Composite; Layer Design;Volume Fill

1 引言

基于体积的铺层填充功能(Volume Fill Composite Part

Development)是FiberSim15.0版本开发出来的新功能,是一个非常强大的自动创建铺层

的设计模块,可以根据所选择零件的封闭曲面来自动生成铺层并进行填充,设计人员只

需在CAD三维软件内对模型进行前处理,提取出相关元素,即上表面、下表面(或中面)、

坐标系原点、坐标方向、设计及工艺边界,并确定所选用的材料,FiberSim便能够自动根

- 2 -

据特定地方的厚度,计算出合适的铺层数目来进行填充,在铺层数目确定后还可以调整

铺层顺序。设计完成后,FiberSim可以根据特定铺层在3D空间的位置,直接生成平面展

开图、三维标注等结果,并导出裁料铺层尺寸及铺层表等图纸文件。该方法尤其适用于

航空发动机风扇叶片或相类似的结构,快速并高效的提升设计及分析阶段的工作效率。

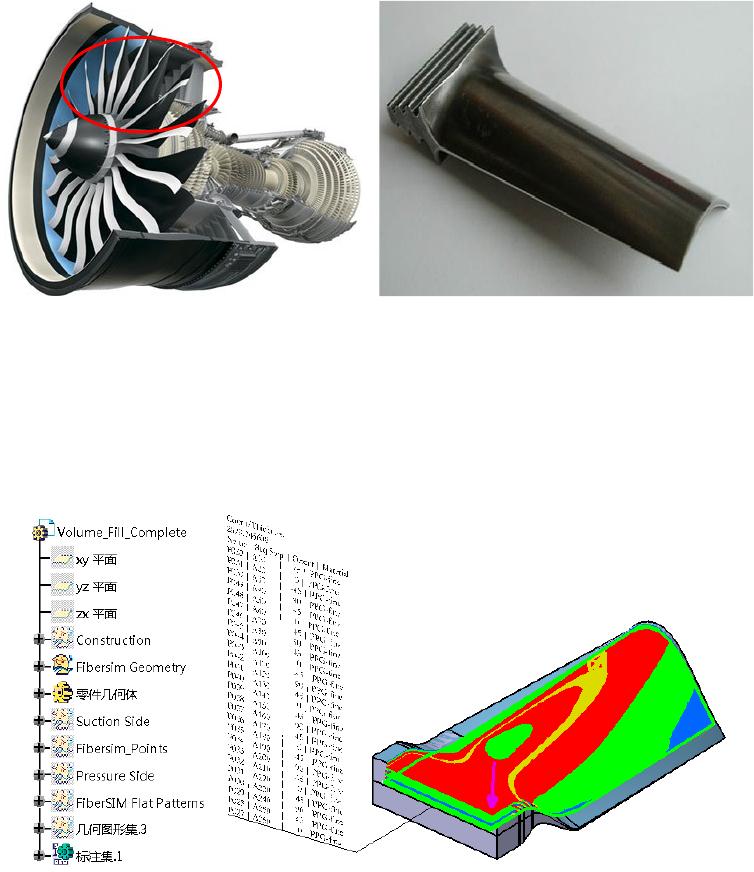

航空发动机风扇叶片结构及在发动机中的位置,如图1所示。

图 1 航空发动机风扇叶片

本文以航空结构件发动机风扇叶片为例,采用Catia软件进行三维建模及零件前处理

,并采用FiberSim软件的Volume

Fill自动体积填充模块进行铺层设计,最终得到相关设计成果以面向实际工艺生产制造。

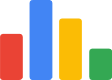

风扇叶片的Catia模型结构树及FiberSim设计成果展示如图2所示。

图 2 发动机风扇叶片设计成果展示

2 Catia&FiberSim设计方法

2.1 创建几何要素

以Catia模型为设计输入,对其进行前处理并创建基本特征几何要素,其中包括:

1) 上表面:提取叶片体上表面,接合后方向朝下,名称为SS_Surface;

of 9

50墨值下载

【版权声明】本文为墨天轮用户原创内容,转载时必须标注文档的来源(墨天轮),文档链接,文档作者等基本信息,否则作者和墨天轮有权追究责任。如果您发现墨天轮中有涉嫌抄袭或者侵权的内容,欢迎发送邮件至:contact@modb.pro进行举报,并提供相关证据,一经查实,墨天轮将立刻删除相关内容。

下载排行榜

评论